Sewage pumps are designed specifically to handle wastewater, which includes not only liquid waste but also solids and debris commonly found in sewage water. These pumps are essential components of sewage systems, helping to transport wastewater from homes, businesses, and industrial facilities to treatment plants or disposal sites. Their ability to handle solids and debris is crucial for the efficient and reliable operation of sewage systems. In this article, we will explore the features and mechanisms that enable sewage pumps to handle solids and debris present in sewage water.

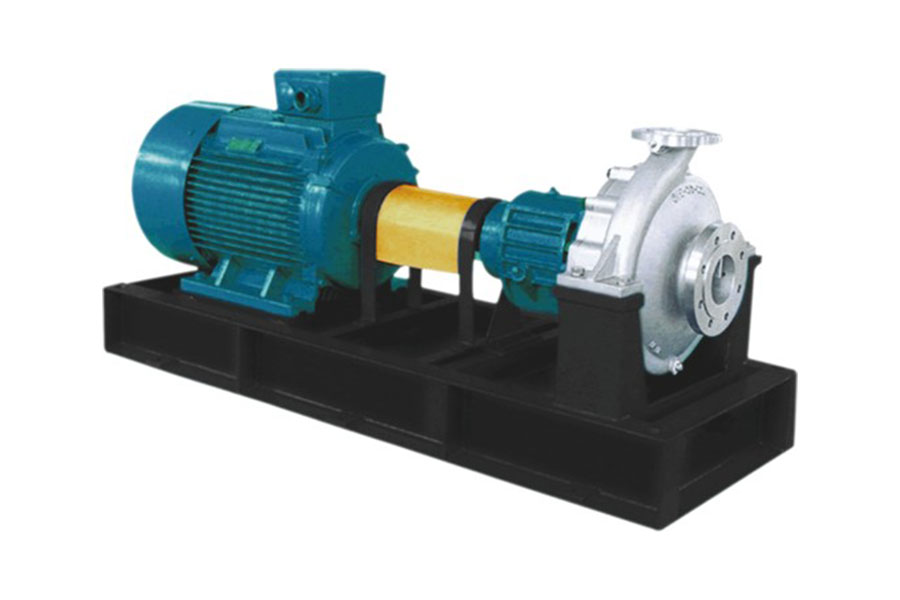

Submersible Sewage Pumps

Submersible sewage pumps are a common type of sewage pump used in various wastewater applications. These pumps are designed to be submerged in the wastewater they are pumping, allowing them to handle both liquid and solids efficiently. Submersible sewage pumps come equipped with features that make them suitable for handling solids and debris:

Solids Handling Capacity: Submersible sewage pumps are specifically engineered with a large inlet and impeller design to handle solid particles and debris of varying sizes. The impeller's robust construction and shape allow it to break down and transport solids effectively without clogging the pump.

Macerators or Grinders: Some submersible sewage pumps are equipped with macerators or grinders. These components are located before the impeller and are responsible for reducing larger solids into smaller, pumpable particles. The macerators or grinders help prevent blockages and ensure smoother wastewater flow.

Vortex Impellers: Some submersible sewage pumps feature vortex impellers. These impellers create a vortex flow pattern within the pump, which allows them to handle larger solids and debris with ease. Vortex impellers are less prone to clogging and are well-suited for applications with high solid content.

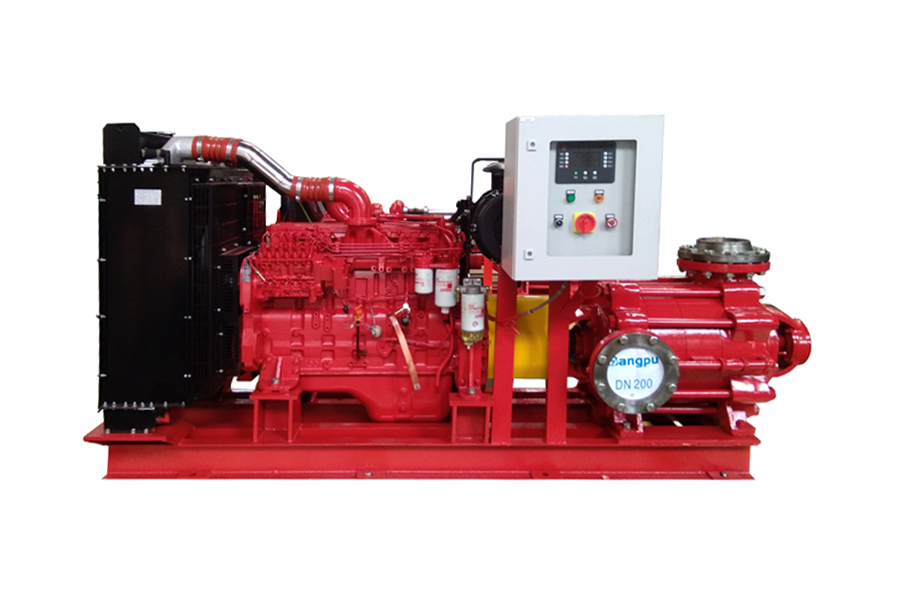

Non-Submersible Sewage Pumps

Non-submersible sewage pumps, also known as dry-installed pumps, are installed above the water level and use suction to draw wastewater into the pump. These pumps are generally used in applications where submersible pumps are not suitable or feasible. While non-submersible pumps are not designed to handle the same level of solids as submersible pumps, they can still handle some solids and debris:

Solids Passage Size: Non-submersible sewage pumps are designed with a specific solids passage size. The size of the solids passage determines the maximum size of solid particles the pump can handle without clogging. Pumps with larger solids passage sizes can handle larger debris and solids.

Design and Material: The design of non-submersible sewage pumps, including the type of impeller used, can influence their ability to handle solids. Pumps with vortex or recessed impellers are generally better equipped to handle solids compared to pumps with standard open impellers.

Strainers and Filters: Some non-submersible sewage pumps are equipped with strainers or filters at the inlet to prevent larger debris from entering the pump and causing clogs.

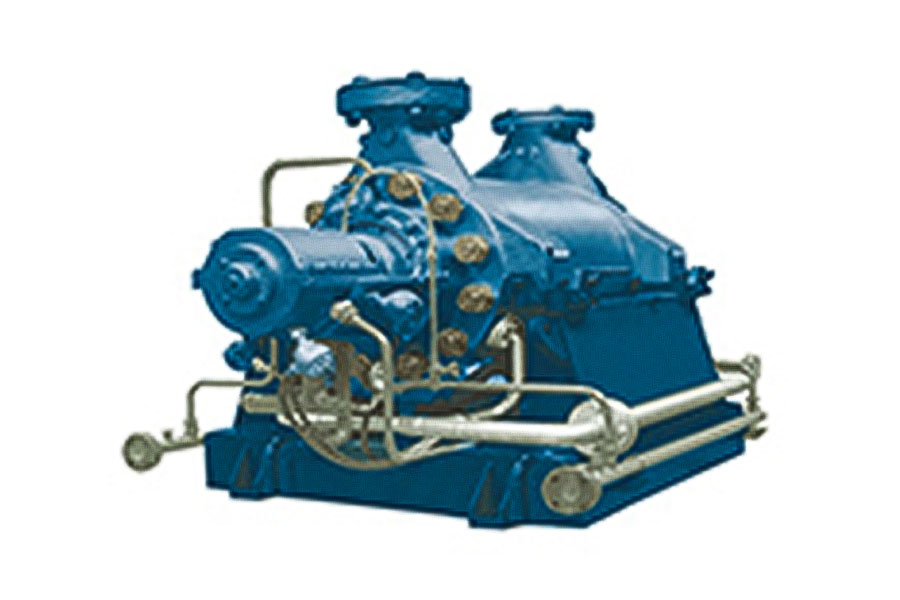

Self-Priming Sewage Pumps

Self-priming sewage pumps are a type of non-submersible sewage pump that can handle both liquids and solids. These pumps are capable of creating a vacuum at the pump inlet, allowing them to draw water and solids from below the pump's level without the need for external priming. Self-priming sewage pumps are useful in situations where the pump needs to handle intermittent flow or where air may enter the suction line.

Grinder Pumps

Grinder pumps are a specialized type of submersible sewage pump equipped with grinding mechanisms to handle larger and tougher solids. These pumps are commonly used in areas with low-flow sewage systems, such as individual homes or small communities. Grinder pumps can macerate solids into smaller, pumpable particles before pumping them through the system, reducing the risk of clogs and ensuring efficient wastewater transport.

Dealing with Stringy Materials

In some cases, sewage pumps may encounter stringy materials such as rags, wipes, or fibrous materials that can cause clogs. To address this challenge, some sewage pumps are equipped with anti-clogging features:

Non-Clog Design: Many sewage pumps are designed with non-clog impellers and casing geometry, reducing the chances of stringy materials getting entangled in the pump.

Cutter or Shredder Mechanisms: Some sewage pumps, especially grinder pumps, are equipped with cutter or shredder mechanisms to break down stringy materials into smaller, manageable pieces.

Maintenance and Cleaning

While sewage pumps are designed to handle solids and debris, regular maintenance and cleaning are essential to ensure their continued efficiency. Periodic inspection, cleaning of pump components, and removal of any accumulated debris will help prevent clogs and ensure the pump's optimal performance.

Sewage pumps are specifically designed to handle the challenging task of transporting wastewater, which often contains a mix of liquids, solids, and debris. Whether submersible, non-submersible, self-priming, or grinder pumps, each type is engineered with features that enable them to handle solids effectively. The design of these pumps, along with features like macerators, vortex impellers, and cutter mechanisms, ensures that they can handle various solid particles and debris commonly found in sewage water without clogging. Regular maintenance and cleaning are essential to keep sewage pumps running efficiently and reliably, preventing any potential issues caused by accumulated solids or debris. Overall, sewage pumps are crucial components in sewage systems, facilitating the safe and efficient transport of wastewater while effectively handling solids and debris.

English

English 中文简体

中文简体

Home

Home