with high efficiency

Wide performance range

Safe and smooth operation

low noise

long life

Easy installation and maintenance

with high efficiency

Wide performance range

Safe and smooth operation

low noise

long life

Easy installation and maintenance

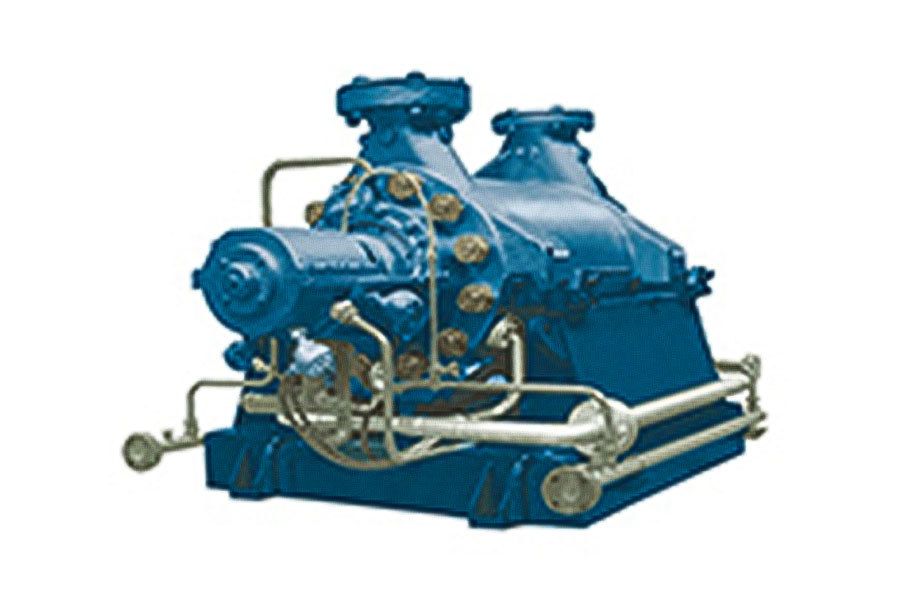

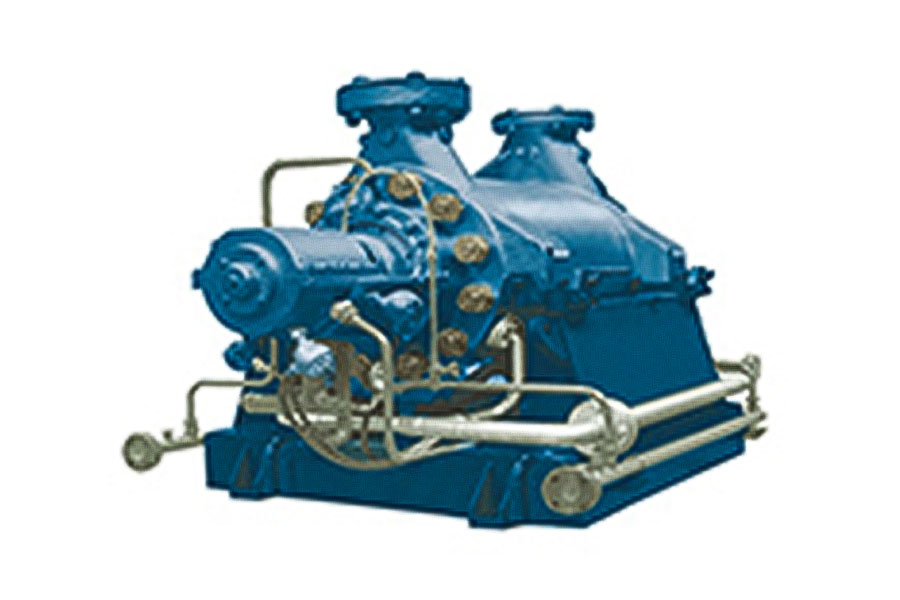

DG type horizontal multi-stage boiler feed pump adopts the hydraulic model of high-efficiency and energy-saving products recommended by the state. It has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. It is suitable for medium and low pressure boiler feed water, high-lift water delivery in factories and cities. For conveying clean water or liquids with physical and chemical properties similar to clean water, the temperature of the conveying medium is -20℃~105℃, and the inlet pressure of the pump shall not exceed 0.59MPa (6kgf/cm2). The inlet and outlet of the pump are both vertically upwards, and the shaft seals include mechanical seals and packing seals. When the pump is sealed with packing, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is advisable that the liquid can seep drop by drop. The rolling bearing is lubricated with grease, the sliding bearing is lubricated with thin oil, and the oil ring is used for self-lubrication, and the circulating water is used for cooling.

|

Capacity |

0.3--280m3/h |

|

Head |

75--650m |

|

Medium temperature |

-20℃--105℃ |

The DG series boiler feed water industrial water pump adopts advanced fluid dynamics design, combined with high-quality materials and exquisite craftsmanship, to ensure efficient, stable and safe operation of the water pump. This series of water pumps adopt advanced fluid dynamics principles in design. Through precise calculation and optimized flow channel design, the resistance of the fluid in the pump body is reduced, thereby improving the pump's delivery efficiency. At the same time, key components such as the impeller and guide vane of the water pump have been carefully processed and balanced to ensure smoother flow of fluid in the pump body and reduce energy loss. DG series boiler feed water industrial water pumps are available in a variety of specifications and models to meet different flow, head and power requirements. Specific technical parameters can be customized according to user requirements. Whether it is a boiler in the electric power, chemical, metallurgical or textile industries, a stable and reliable water supply system is required to ensure the normal operation of the boiler. DG series water pumps can meet the water supply needs of boilers of different sizes and types.

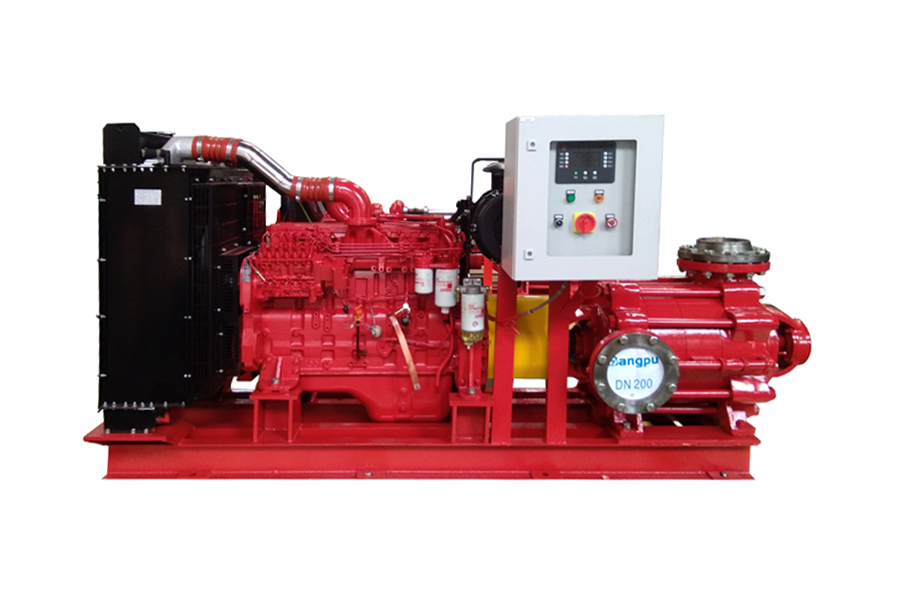

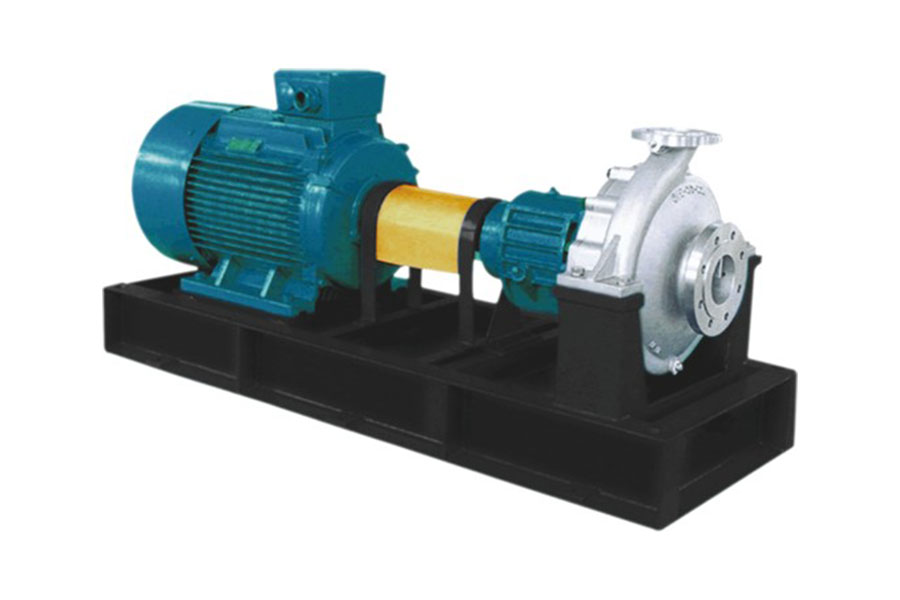

Shanghai Bangpu Industrial Group Co., Ltd. is a large group enterprise specializing in R & D and manufacturing all kinds of fluid transmission equipment in China. Since its establishment, the group has implemented diversified operation, with pumps, valves, energy-saving motors and complete sets of water supply and drainage equipment as its basic business, and the production, sales, import and export business of sewage treatment, environmental protection equipment and related accessories as its extension.

Shanghai Bangpu as China Wholesale Industrial Water Pump Suppliers and OEM/ODM DG series boiler feed Industrial water pump Company, it produces a variety of products with complete specifications. Its main products include frequency conversion and constant pressure water supply equipment, pipe network laminated water supply equipment, box-type laminated water supply equipment, remote monitoring system, water pumps and various electrical control equipment.

Since its establishment, through continuous competition with other complete sets of secondary water supply equipment manufacturers and continuous self-accumulation, the company has won the height of end users in terms of core technology, differentiated design customization, quality consistency assurance, and continuous and stable recognized.

On February 9, 2018, the signing and unveiling cer...

Read more

In recent days, it has generally cooled and snowed...

Read more

1. Electric motor fire pump set (9 series, a total...

Read more

The company participated in the China Urban Water ...

Read more

In January 2017, the company launched the environm...

Read more

In order to improve the corporate image, the compa...

Read more

In order to improve the product quality of the ent...

Read more

In order to meet the market demand, the company de...

Read more

Through unremitting efforts and many visits by cus...

Read more

In June 2017, in order to ensure the smooth commis...

Read more

On February 18, 2017, the annual company's annual ...

Read more

The group company has passed the re-certification ...

Read moreHigh efficiency and energy saving: The DG series boiler feed water pump adopts the high-efficiency and energy-saving hydraulic model recommended by the country. This design allows the pump to more efficiently convert electrical energy or thermal energy into the kinetic energy and potential energy of the fluid during operation, thus improving the energy efficiency of the pump.

Wide performance range: DG series boiler feed water pumps have a wide performance range and can adapt to different flow and head requirements. This allows the pump to adjust operating parameters according to actual working conditions during operation, avoiding excessive energy consumption and further improving energy efficiency.

Safe and stable operation: The rotor part of the DG series boiler feed water pump adopts balancing measures such as a balance plate, which can effectively balance the axial force and make the pump more stable during operation. This smooth operation helps reduce energy consumption and wear, extending the life of the pump.

Low noise: DG series boiler feed water pumps pay attention to reducing noise during the design and manufacturing process, and use components such as low-noise bearings and seals. This allows the pump to operate with lower noise, improves the working environment and reduces energy consumption due to noise.

Easy installation and maintenance: DG series boiler feed water pumps adopt a modular design, making the installation and maintenance of the pump more convenient. This design helps reduce installation and repair time and maintenance costs while also improving pump operating efficiency.

Optimize mechanical structure design:

Shaft design: increase the number of drive shaft support bearings, reduce the support spacing, reduce the shaft length within an appropriate range, appropriately increase the diameter of the shaft, and increase the stiffness of the shaft. At the same time, avoid the relationship between the pump shaft speed and the natural vibration frequency of the pump rotor to be close to or an integer multiple to reduce vibration caused by resonance.

Selection of sliding bearings: In specific applications (such as chemical pumps such as liquid hydrocarbons), materials with good self-lubricating properties such as polytetrafluoroethylene are selected as sliding bearing materials. In deep well hot water pumps, the diversion bushing may be filled with polytetrafluoroethylene, graphite and copper powder, and its structure may be reasonably designed to improve fixation reliability.

Design of impeller and sealing ring: Friction material with small friction coefficient, such as M20lK graphite material-steel, is used at the impeller sealing ring and pump body sealing ring to reduce friction and vibration.

Improve manufacturing and assembly quality:

Improve the manufacturing quality of the shaft and prevent mass eccentricity and excessive geometric tolerance.

During the assembly process, pay attention to the alignment of the coupling to avoid problems such as damage to the elastic block of the coupling and too small coupling clearance.

Choose high-quality bearings, such as SKF imported bearings, to avoid vibration caused by bearing quality problems.

Use shock absorption and sound insulation measures:

Install rubber shock-absorbing pads or linkage supports and other shock-absorbing measures on the support frame of the boiler feed water pump to reduce the impact of vibration on the equipment and the surrounding environment.

Install a soundproof cover or soundproofing material around the boiler feed water pump to reduce the spread of noise.

Reasonable installation and debugging:

Ensure that the installation height of the water pump meets the design requirements to avoid vibration and noise problems caused by insufficient installation height.

Warm the pump before starting the machine to avoid vibration and noise caused by temperature differences.

Applications of intelligent control systems:

Through the intelligent control system, automatic control of the boiler feed water pump is realized, such as controlling the start and stop of the water pump, speed adjustment, etc., to reduce noise and vibration.

The comprehensive application of the above measures can effectively reduce the noise and vibration generated by the DG series boiler feed water pump during operation and improve the operating efficiency and stability of the equipment.