A self-priming centrifugal pump and a standard centrifugal pump are both devices used to move fluids, but they differ significantly in terms of their priming capabilities. Priming is the process of removing air or gas from the pump and suction line to create a vacuum and enable the pump to efficiently draw and move the fluid. In this response, we'll delve into the key differences between self-priming centrifugal pumps and standard centrifugal pumps in terms of their priming capabilities.

1. Priming Mechanism:

The fundamental difference between a self-priming centrifugal pump and a standard centrifugal pump lies in how they achieve the priming process.

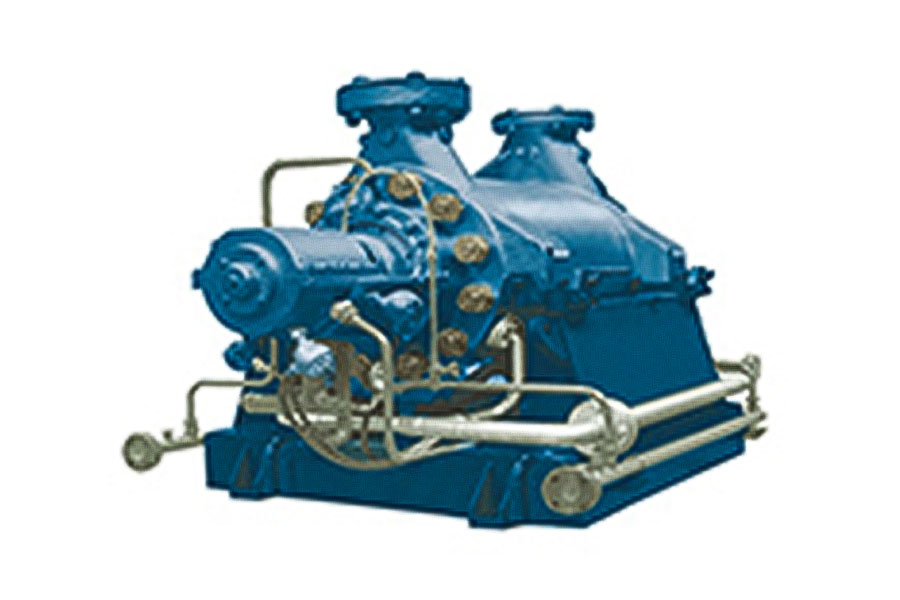

Standard Centrifugal Pump: In a standard centrifugal pump, priming is a manual or external process. Before startup, the pump and suction line must be filled with liquid to eliminate air or gas. This often involves the use of additional equipment like priming chambers, foot valves, or manual filling. If the pump runs dry or loses its prime due to air infiltration, it must be manually re-primed to resume operation.

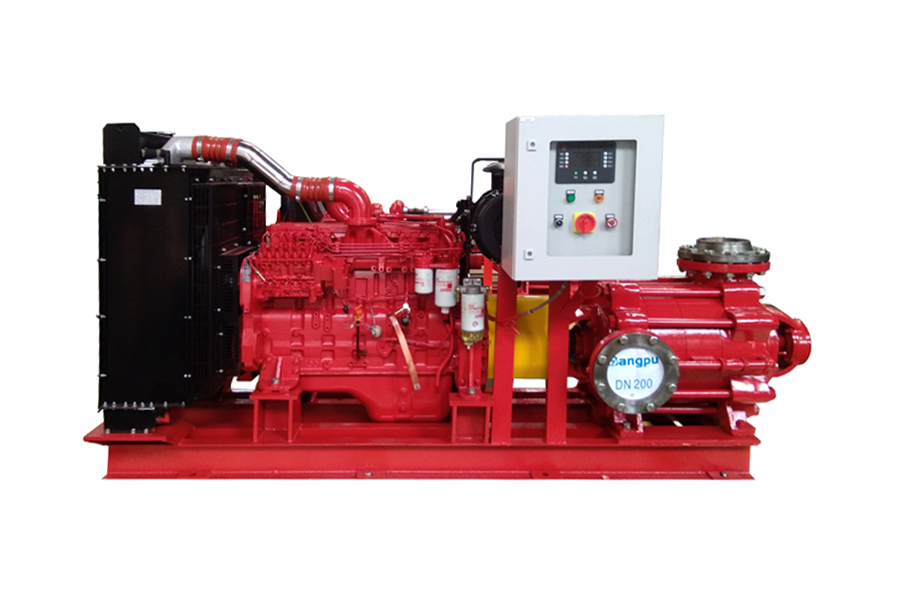

Self-Priming Centrifugal Pump: A self-priming centrifugal pump, on the other hand, has a built-in mechanism that allows it to automatically and repeatedly prime itself. These pumps are designed with a special casing or chamber, known as a priming chamber or reservoir, that can retain a small amount of liquid even when the pump is not in operation. When the pump starts, this retained liquid is used to create the initial vacuum, expel air, and initiate the priming process. As a result, self-priming centrifugal pumps can re-prime themselves after temporary loss of prime due to air or gas intrusion.

2. Air Handling Capability:

Another crucial difference is how these pumps handle air and gas entrainment.

Standard Centrifugal Pump: Standard pumps are less capable of handling air or gas within the fluid. When they encounter air, cavitation can occur, which can damage the impeller and other pump components. Continuous air ingress can disrupt operation and require manual intervention to re-prime.

Self-Priming Centrifugal Pump: Self-priming pumps are specifically designed to handle air and gas entrainment. They can evacuate air from the suction line and the pump casing, creating a stable vacuum for efficient fluid transfer. This capability makes self-priming pumps ideal for applications where air may intermittently enter the system, such as when pumping from a low-lying source or dealing with variable fluid levels.

3. Application Flexibility:

The differences in priming capabilities also influence the types of applications where these pumps are most suitable.

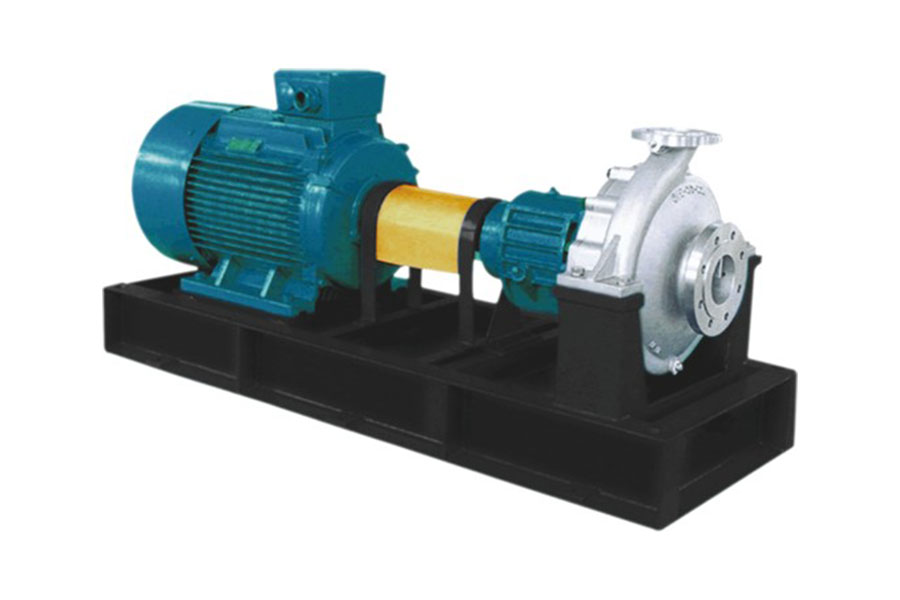

Standard Centrifugal Pump: Standard centrifugal pumps are typically used in applications where a continuous and consistent flow of liquid is maintained, and there is no risk of losing prime due to air or gas ingress. They are widely used in various industrial processes and water distribution systems.

Self-Priming Centrifugal Pump: Self-priming pumps excel in applications where the fluid source is below the pump's elevation, or when intermittent air entrainment is likely. Common applications include sewage and wastewater handling, dewatering operations, irrigation, and chemical transfer. They are especially valuable in situations where ease of operation and reduced maintenance are priorities.

4. Priming Time and Efficiency:

Standard Centrifugal Pump: Standard pumps typically require manual priming, which can be time-consuming and may lead to downtime if air enters the system. The priming time can vary depending on factors such as the pump size and the length of the suction line.

Self-Priming Centrifugal Pump: Self-priming pumps offer quick and automatic priming, reducing startup time and the need for constant monitoring. This efficiency can be critical in applications where rapid response or continuous operation is essential.

5. Maintenance and Reliability:

Standard Centrifugal Pump: While standard pumps are reliable when properly primed, they may require more frequent maintenance and monitoring to ensure that they remain primed in challenging conditions.

Self-Priming Centrifugal Pump: Self-priming pumps are designed for increased reliability in applications with variable conditions. Their ability to re-prime automatically minimizes the risk of pump damage and system downtime.

In conclusion, the key difference between a self-priming centrifugal pump and a standard centrifugal pump lies in their priming capabilities. Self-priming pumps are designed to automatically evacuate air, initiate priming, and re-prime themselves when necessary, making them well-suited for applications with variable fluid levels and intermittent air entrainment. Standard centrifugal pumps, while reliable in their own right, require manual priming and are best suited for applications with a continuous and consistent flow of liquid. Understanding these differences is essential when selecting the appropriate pump for a specific application, as it can greatly impact performance, efficiency, and maintenance requirements.

English

English 中文简体

中文简体

Home

Home