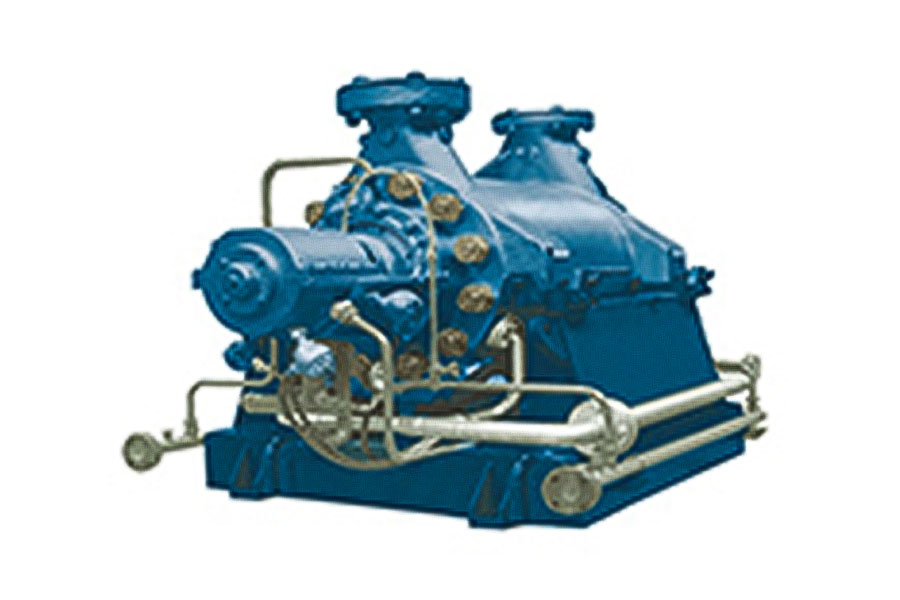

The double-suction design is a feature of centrifugal pumps that can significantly impact their efficiency. In this design, the pump's impeller is positioned between two suction openings, allowing liquid to enter from both sides. This unique configuration offers several advantages that enhance the overall performance of the pump.

One of the main benefits of the double-suction design is its symmetric nature. With two suction openings, the hydraulic forces on the impeller are balanced, reducing thrust loads on the shaft and bearings. This results in improved stability, reduced vibration, and increased longevity of the pump components. Additionally, the balanced nature of the impeller reduces the shaft deflection, which further improves the pump's overall efficiency.

Another advantage of the double-suction configuration is its ability to provide a more uniform flow distribution to the impeller. The two suction openings help to evenly distribute the fluid across the impeller, reducing any uneven stresses or flow disturbances. This balanced distribution leads to smoother operation, minimizing cavitation and ensuring optimal pump performance.

Furthermore, the double-suction design allows for larger impeller eye areas compared to single-suction pumps. The impeller eye is the region through which the fluid enters the impeller. The larger impeller eye area in the double-suction design results in reduced entrance losses and improved flow characteristics. This improved flow efficiency leads to higher overall pump efficiency.

The double-suction design also offers advantages in terms of inlet conditions. Traditional single-suction pumps often require straight inlet piping to ensure a uniform flow into the impeller. However, the double-suction design is more forgiving when it comes to inlet conditions. It can accommodate a certain degree of uneven piping distributions, bends, and other fittings without significantly affecting performance. This feature not only simplifies installation but also reduces the overall system cost by eliminating the need for extensive inlet piping modifications.

In terms of specific energy consumption, the double-suction design can provide energy savings compared to single-suction centrifugal pumps. By ensuring a balanced flow and reducing inlet losses, the pump can operate more efficiently. This efficiency improvement results in reducing the power requirements for a given flow rate, consequently reducing energy consumption and operating costs.

Nevertheless, it is important to note that the efficiency improvement with the double-suction design is not without limitations. In some cases, specifically in smaller pump sizes, the double-suction configuration may introduce increased hydraulic losses due to the larger impeller eye area. These losses can reduce the efficiency of the pump. Therefore, it is crucial to consider the specific pump size and operating conditions when selecting between single-suction and double-suction designs for optimum efficiency.

In conclusion, the double-suction design significantly affects the efficiency of centrifugal pumps. Its balanced and symmetric nature reduces thrust loads, improves stability, and increases the longevity of pump components. Additionally, the improved flow distribution, larger impeller eye area, and tolerance to inlet conditions contribute to enhanced pump performance and efficiency. Although there may be limitations, in general, the double-suction design can offer energy savings and lower operating costs in comparison to single-suction centrifugal pumps. It is essential to carefully consider the specific application and operating conditions to select the most suitable pump design for maximum efficiency.

English

English 中文简体

中文简体

Home

Home