A horizontal single-stage centrifugal pump is a fundamental piece of equipment widely used in various industries to transport fluids, whether it be water, chemicals, oil, or other liquids. Its design features play a critical role in its efficiency, performance, and versatility. In this comprehensive explanation, we will delve into the key design features of a horizontal single-stage centrifugal pump.

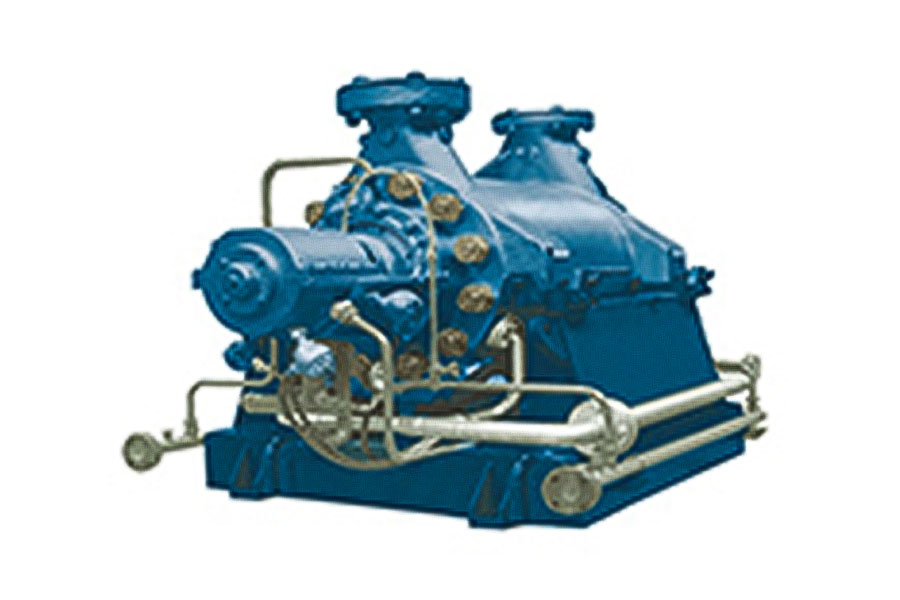

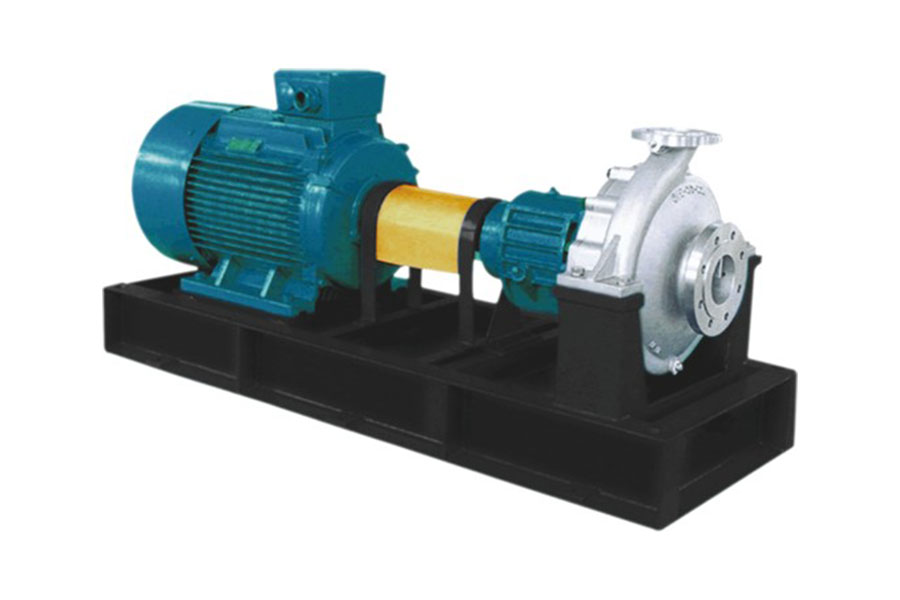

1. Impeller: The heart of any centrifugal pump is its impeller. In the case of a single-stage centrifugal pump, there is just one impeller. This impeller is a rotating disk with curved vanes or blades. Its primary function is to impart kinetic energy to the fluid. As the impeller spins, it draws the fluid in and accelerates it radially outward, creating a flow of fluid with increased velocity.

2. Casing: The impeller is enclosed within a casing, which is typically spiral-shaped. The casing's purpose is to convert the high-velocity kinetic energy of the fluid into pressure energy. This happens as the fluid flows through the casing, and its velocity decreases while its pressure increases. The casing is a critical part of the pump's design as it influences the efficiency and performance.

3. Inlet and Outlet Ports: The pump has an inlet port where the fluid enters and an outlet port where the pressurized fluid exits. These ports are carefully designed to facilitate the smooth and efficient flow of fluid through the pump. The size and shape of these ports are critical considerations in the design to minimize turbulence and energy loss.

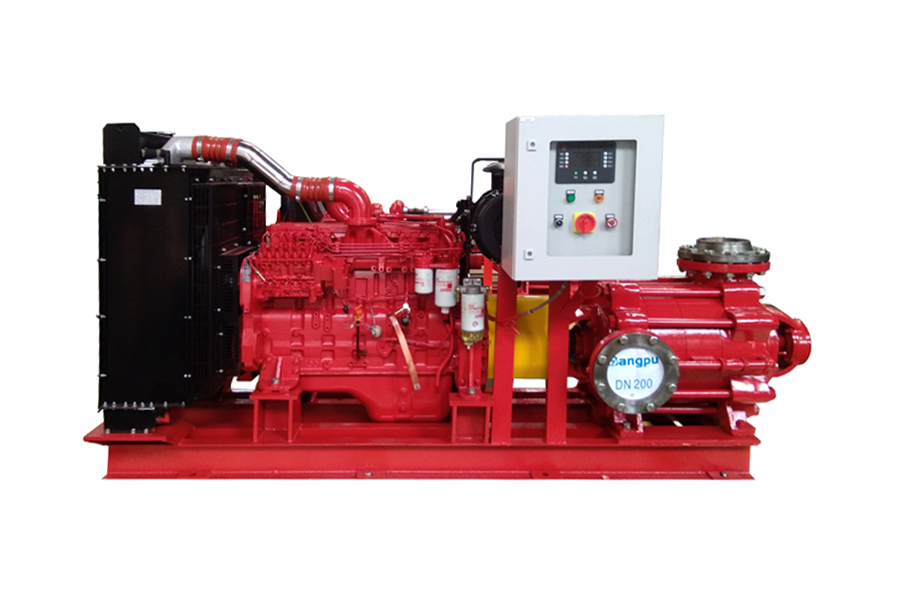

4. Shaft and Bearings: To rotate the impeller, there is a shaft that extends through the pump. It is connected to a driver, usually an electric motor or an engine. Bearings support the shaft, allowing it to rotate smoothly and with minimal friction. Proper bearing design is crucial for reducing wear and extending the pump's lifespan.

5. Seals: To prevent leakage of fluid from the pump, seals are installed at various points, such as around the shaft where it enters the casing. Proper sealing is essential to maintain the integrity of the pump and prevent contamination or environmental damage.

6. Wear Rings: Wear rings are often incorporated into the design of the pump, especially in high-pressure applications. They are located at the impeller's inlet and outlet edges and the casing's corresponding surfaces. These rings help minimize friction and wear, thus enhancing the pump's durability and efficiency.

7. Suction and Discharge Nozzles: These are components located at the inlet and outlet ports, respectively. They are designed to connect the pump to the pipeline system. The size and shape of these nozzles are essential considerations in optimizing the pump's performance and minimizing energy losses.

8. Priming System: In some cases, horizontal single-stage centrifugal pumps require priming to remove any air or gas from the pump's casing and suction pipe to ensure proper operation. The design may include a priming system that facilitates this process.

9. Materials of Construction: The choice of materials for various pump components is critical, especially in applications involving corrosive or abrasive fluids. Materials like stainless steel, cast iron, bronze, and various polymers are commonly used to ensure durability and chemical compatibility.

10. Motor or Driver Coupling: Horizontal single-stage centrifugal pumps are typically powered by electric motors or engines. The design should include a coupling mechanism that connects the pump's shaft to the motor or driver, efficiently transferring power.

11. Baseplate or Foundation: The pump must be mounted on a stable baseplate or foundation to ensure proper alignment and minimize vibration. The design of this support structure is crucial for the long-term reliability of the pump.

12. Control and Monitoring Instruments: In modern pump designs, there may be integrated control and monitoring instruments to measure parameters such as flow rate, pressure, temperature, and motor performance. These instruments allow for real-time monitoring and control of the pump's operation.

13. Efficiency Enhancements: Depending on the specific application, various efficiency-enhancing features may be incorporated into the design. This could include special impeller designs, variable speed drives, or advanced computational fluid dynamics (CFD) analysis to optimize the pump's performance.

In conclusion, a horizontal single-stage centrifugal pump is a versatile piece of equipment designed to efficiently transport fluids in various industrial applications. Its key design features, including the impeller, casing, bearings, seals, and many others, work together to ensure reliable and efficient operation. Proper consideration of these design elements is essential in selecting and maintaining a pump that meets the specific requirements of a given application while minimizing energy consumption and maximizing longevity.

English

English 中文简体

中文简体

Home

Home