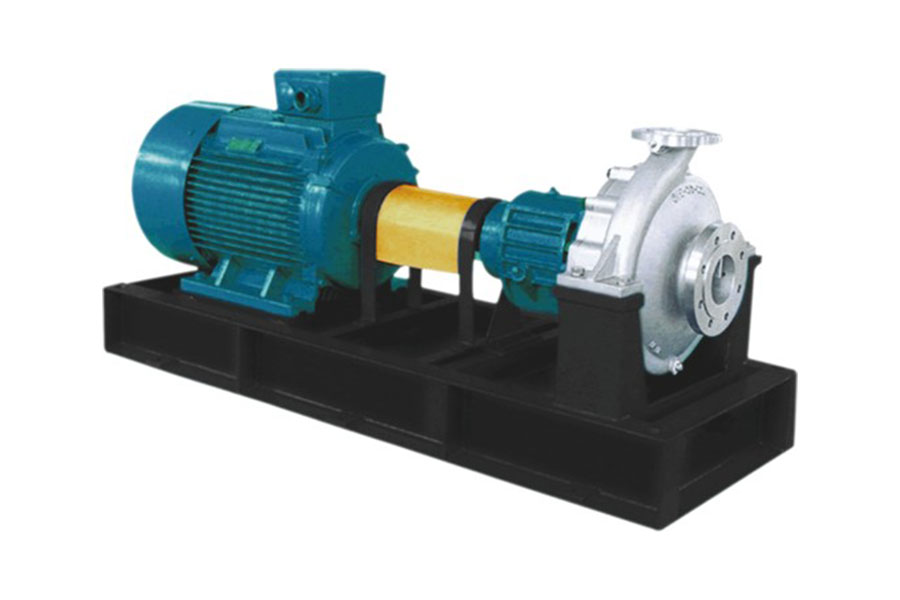

Horizontal multistage chemical process pumps are highly versatile and capable of delivering a wide range of fluids, including but not limited to:

Clean Water: These pumps can efficiently handle clean water, making them suitable for various applications, including municipal water supply and distribution.

Corrosive Chemicals: They are designed to transport aggressive and corrosive chemicals commonly found in industrial processes. This includes acids, alkalis, solvents, and other corrosive liquids used in chemical manufacturing and processing.

High-Temperature Liquids: Horizontal multistage pumps can handle high-temperature fluids, making them suitable for applications where elevated temperatures are encountered, such as in refineries and petrochemical plants.

Viscous Fluids: Some models of these pumps are designed to handle viscous fluids, including polymers, adhesives, and various process fluids with higher viscosities.

Abrasive Slurries: In certain configurations, these pumps can transport abrasive slurries containing solid particles. They are commonly used in mining and mineral processing to move abrasive materials.

Petrochemical Products: These pumps are employed in the petrochemical industry to transfer products such as crude oil, refined hydrocarbons, and various petrochemical derivatives.

Pharmaceutical Ingredients: In the pharmaceutical industry, horizontal multistage pumps are used to safely transfer chemicals, solvents, and active pharmaceutical ingredients (APIs) for drug manufacturing.

Food and Beverage Ingredients: They can handle food-grade chemicals and ingredients, including flavorings, preservatives, and acids, used in the production of beverages and processed foods.

Water Treatment Chemicals: Municipal and industrial water treatment plants utilize these pumps for dosing and injecting chemicals like chlorine, coagulants, and flocculants into the water treatment process.

Specialty Chemicals: These pumps can transport a wide range of specialty chemicals used in various industries, including textiles, plastics, and specialty chemical manufacturing.

It's important to note that the choice of materials for the pump's construction, seals, and coatings is critical to ensure compatibility with the specific fluid being transported. Different models and configurations of horizontal multistage chemical process pumps are available to meet the unique requirements of different fluids and industries, making them a versatile solution for various industrial applications. Proper material selection and maintenance are essential to ensure the pump's longevity and performance when handling different fluids.

English

English 中文简体

中文简体

Home

Home