In the complex system of industrial production, the boiler is a key energy conversion equipment, and its stable operation is crucial to the smoothness of the entire production process and the energy utilization efficiency. As one of the core equipment to ensure the continuous and efficient operation of the boiler, the DG series boiler feed water industrial water pump plays an indispensable role in reducing energy loss and improving the energy utilization efficiency of industrial production with its stability and sealing performance.

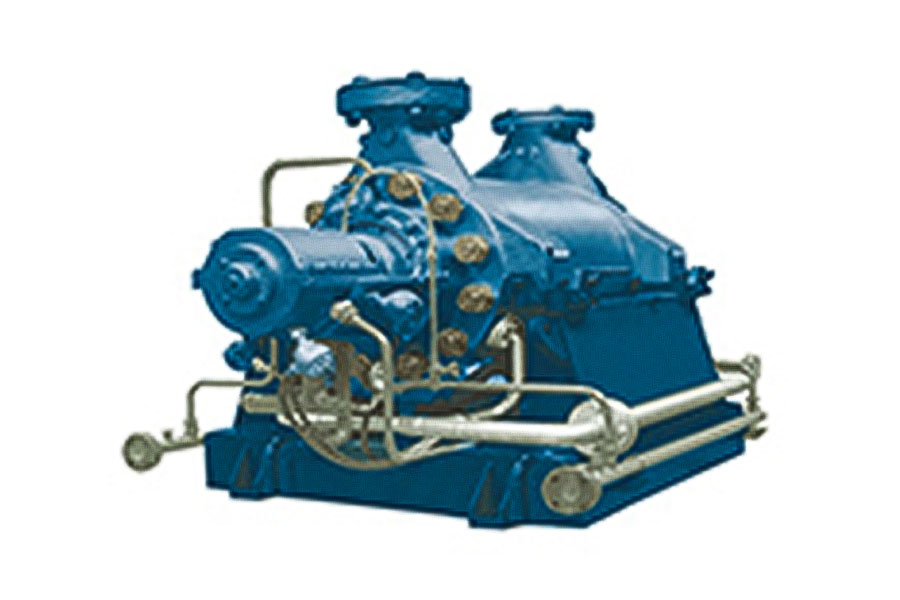

From the perspective of working principle, the stability of the DG series boiler feed Industrial water pump comes from its precise mechanical structure and carefully adjusted power transmission system. This series of water pumps uses high-precision impellers and advanced bearing components. The impeller has undergone rigorous dynamic balancing tests to ensure that it can maintain uniform centrifugal force output during high-speed rotation and avoid vibration and unstable operation caused by impeller imbalance. The bearing components use high-quality materials and advanced lubrication technology to effectively reduce rotational friction and further improve the stability of the water pump operation. This stability enables the water pump to continue to operate in an efficient mode during long-term operation, providing constant pressure and flow of water for the boiler. Stable water supply is of great significance to the stable operation of the boiler. It ensures that the water level in the boiler remains within a reasonable range and avoids the decline in combustion efficiency and energy waste caused by excessive water level fluctuations. For example, when the boiler is in high-load operation, if the water pump cannot supply water stably, the boiler water level may drop too quickly. At this time, the boiler control system may increase the fuel input to maintain steam production, which will undoubtedly increase energy consumption. The stable operation of the DG series water pump can effectively avoid this situation and ensure that the boiler always operates in an efficient and stable state, thereby reducing unnecessary energy loss.

Sealing performance is another major advantage of the DG series boiler feed Industrial water pump. It plays a key role in preventing liquid leakage and improving energy utilization efficiency. This series of water pumps uses advanced sealing technology at the shaft seal. Whether it is the common soft packing seal or the high-performance mechanical seal equipped with some models, they have been carefully designed and optimized. The soft packing seal forms a tight sealing ring at the shaft seal through a specially formulated fiber material, which effectively prevents liquid from leaking along the shaft. At the same time, this sealing method has a certain degree of flexibility and can adapt to the slight swing of the shaft during operation to ensure the durability of the sealing effect. The mechanical seal adopts a more sophisticated structure. The sealing assembly consists of a static ring, a dynamic ring, an elastic element, etc. When the pump is running, the dynamic ring and the static ring fit tightly together to form an almost leak-free sealing barrier. This sealing performance effectively prevents the leakage of high-pressure liquid in the pump and avoids energy loss caused by leakage. It should be noted that liquid leakage will not only cause waste of water resources, but also cause the pump to consume additional energy during operation to compensate for the flow loss caused by leakage. The good sealing performance of the DG series water pump ensures that the liquid in the pump flows along the predetermined path, maximizes the energy utilization efficiency, and enables the water pump to provide stable water supply to the boiler with higher energy efficiency.

From the overall design of the equipment, the DG series boiler feed Industrial water pump organically combines stability and sealing performance. Its pump body adopts high-strength materials and optimized structural design, which not only ensures the long-term stable operation of the water pump under high-pressure environment, but also provides a reliable installation foundation for the sealing assembly. For example, the rigid structure of the pump body effectively reduces the deformation caused by external forces, thereby avoiding the misalignment and leakage risks of the sealing surface. At the same time, the internal flow channel design of the water pump also fully considers the requirements of stability and sealing performance. The smooth flow channel surface reduces the impact of water flow on the pump body and sealing components, further extending the service life of the equipment and the durability of the sealing performance. This integrated design concept enables the DG series water pumps to show performance in industrial applications and provides a solid guarantee for energy saving and consumption reduction in industrial production.

English

English 中文简体

中文简体

Home

Home