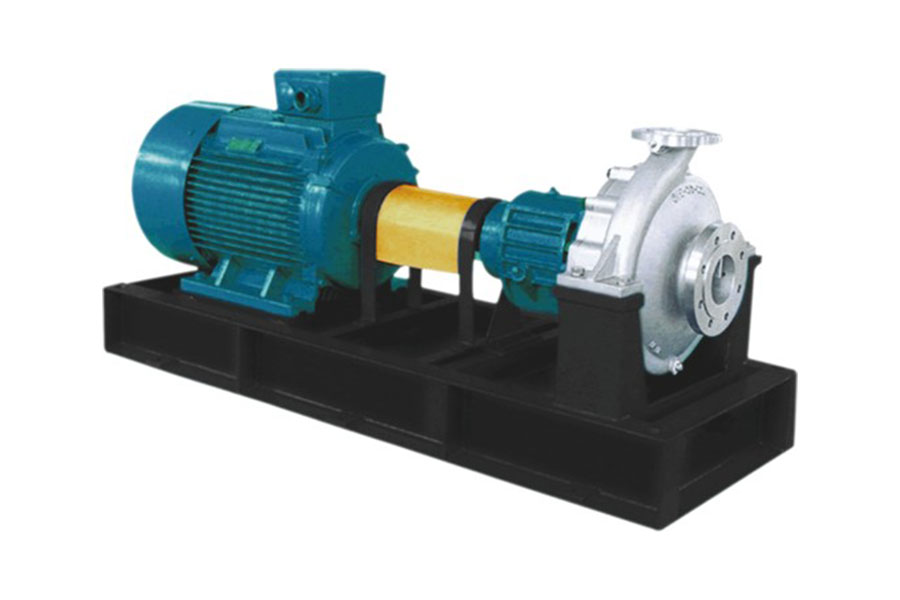

In the fluid delivery system of modern industrial and civil facilities, the BPF variable frequency pump has become an ideal choice in many fields with its high efficiency, energy saving, stable and reliable operation characteristics. As the core control unit of the entire system, the BPF variable frequency pump control panel shoulders the heavy task of real-time monitoring and precise regulation, especially in automatically adjusting the pump operating frequency according to key parameters such as flow and pressure, showing excellent technical advantages and intelligent level.

The BPF variable frequency pump control panel integrates advanced sensor interfaces and data processing modules, which can achieve seamless docking with flow sensors, pressure sensors, etc. installed in the pipeline system. These sensors are like the "tentacles" of the control panel, sensing the dynamic changes of the fluid in the pipeline at all times, quickly converting analog signals such as flow and pressure into digital signals, and transmitting them to the control panel in real time. As the core computing component, the microprocessor in the control panel uses complex and efficient algorithms to perform high-speed parsing and analysis on the received massive data. When the flow or pressure data deviates from the preset target value, the microprocessor will calculate the pump operating frequency that needs to be adjusted to restore the system to stability in a very short time.

From the perspective of technical principles, the BPF variable frequency pump control panel adopts a closed-loop control strategy. It uses preset flow, pressure and other parameters as target values, and continuously compares the actual values collected by the sensor in real time with them. Once there is a deviation between the two, the control panel immediately generates a control signal, and accurately adjusts the power supply frequency of the pump motor through the variable frequency drive device. As the power source of the pump, the motor has a linear relationship between its speed and the power supply frequency. When the power supply frequency increases, the motor speed increases, and the impeller rotation speed of the pump increases, thereby increasing the fluid delivery per unit time, achieving flow increase and pressure stability; conversely, when the power supply frequency decreases, the motor speed slows down, and the output flow and pressure of the pump decrease accordingly. This closed-loop control mode based on real-time feedback ensures that the operating frequency of the pump can follow the changes in the system working conditions, achieve accurate and dynamic adjustment, and maintain the system in a stable and efficient operating state at all times.

In actual application scenarios, this precise frequency adjustment function of the BPF variable frequency pump control panel plays an irreplaceable and important role. In urban water supply systems, water demand varies greatly at different times. In the early morning and evening, residents use water intensively, and the water consumption rises sharply, and the pipeline pressure faces the risk of a sudden drop. At this time, the BPF variable frequency pump control panel, with its keen data collection capabilities, quickly captures the signal of pressure drop and flow surge, and immediately increases the operating frequency of the pump to increase the water supply, ensure the stability of water pressure in thousands of households, and meet the daily water needs of residents. In the middle of the night, the water consumption is greatly reduced, and the control panel timely reduces the pump frequency to avoid excessive operation of the pump and energy waste, and extend the service life of the equipment.

In the field of industrial production, the production processes of chemical, pharmaceutical and other industries have almost strict requirements on the stability and accuracy of fluid transportation. The BPF variable frequency pump control panel can pre-set precise flow and pressure parameters according to the specific needs of different production processes. During the production process, if the flow and pressure in the pipeline fluctuate due to factors such as reaction progress and equipment operation status, the control panel can respond quickly and automatically adjust the pump frequency to ensure that the material delivery volume accurately matches the production rhythm, ensure the continuity of the production process and the stability of product quality, and avoid production accidents and product defective rates caused by out-of-control flow and pressure.

The BPF variable frequency pump control panel achieves accurate and dynamic adjustment of the pump operating frequency through real-time monitoring and intelligent analysis of parameters such as flow and pressure, with the help of closed-loop control technology and variable frequency drive system. This core function not only provides efficient and stable operation guarantee for various fluid conveying systems, but also shows significant advantages in energy saving and consumption reduction, improving production efficiency, and ensuring product quality. It has become a key technical force to promote the intelligent and efficient development of modern industrial and civil facilities. With the continuous advancement of science and technology, the BPF variable frequency pump control panel is expected to expand its application in more fields and contribute more value to social development.

English

English 中文简体

中文简体

Home

Home