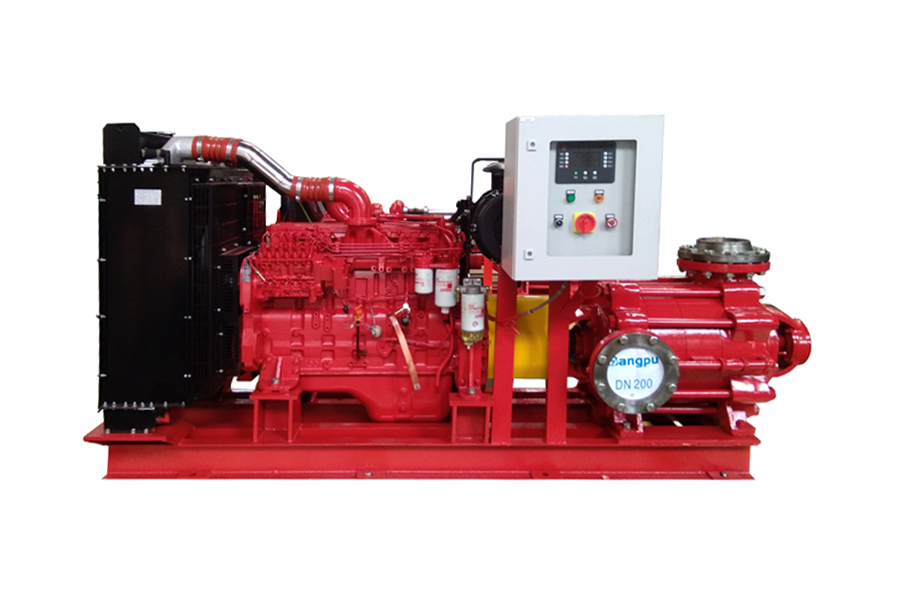

In the fire safety guarantee system, the XBC-IS diesel engine fire pump occupies a pivotal position. Its excellent performance is not only reflected in its powerful water pumping and fire extinguishing capabilities, but also in its all-round real-time monitoring of its own operating status and automatic fault alarm protection mechanism. This key feature ensures that the equipment can operate stably and reliably at critical moments, providing a solid guarantee for the effective extinguishing of fires.

A sophisticated and complex monitoring system is built inside the XBC-IS diesel engine fire pump, like an always alert "intelligent guard", which continuously monitors the key operating parameters of the diesel engine in detail. The monitoring system integrates a variety of advanced sensor technologies and can keenly capture subtle changes in the operation of the diesel engine. Taking low oil pressure monitoring as an example, when the lubricating oil pressure inside the diesel engine shows an abnormal downward trend, the pressure sensor will quickly sense this change and transmit the pressure data to the central control system of the fire pump in real time. Similarly, for the monitoring of high water temperature, the temperature sensor is like a "thermometer", which fits closely to the key heating parts of the diesel engine. Once the water temperature exceeds the normal working range, it will immediately feedback abnormal information to the central control system.

As the "smart brain" of the XBC-IS diesel engine fire pump, the central control system undertakes the core tasks of data reception, analysis and command issuance. When it receives fault signals such as low oil pressure and high water temperature from the sensor, it will quickly conduct in-depth analysis of these data based on the preset logical algorithm to accurately determine the type, severity and possible impact range of the fault. Once the fault is confirmed to be true, the central control system will immediately activate the automatic alarm protection mechanism. This mechanism is like sounding an emergency alarm, sending a strong warning signal to the surrounding environment through the sound and light alarm device, reminding the on-site operator that the equipment has failed and needs to take immediate countermeasures. At the same time, the alarm information will also be quickly transmitted to the remote monitoring center in the form of digital signals through wired or wireless communication networks, so that managers who are not on site can also grasp the abnormal conditions of the equipment at the first time.

From the design concept point of view, the automatic alarm protection mechanism of the XBC-IS diesel engine fire pump is significantly forward-looking and scientific. It greatly improves the safety and reliability of firefighting operations. In the emergency moment of a fire, the stable operation of the fire pump is crucial. If the diesel engine is poorly lubricated due to low oil pressure, it may cause excessive wear or even jamming of parts, making the fire pump unable to operate normally; high water temperature may cause the diesel engine to overheat, damage engine parts, and seriously affect the working performance of the fire pump. With the automatic alarm protection mechanism, operators can learn about the fault situation at the first time and quickly take targeted measures such as replenishing lubricating oil and checking the cooling system to avoid further deterioration of the fault, ensure that the fire pump can continue to operate efficiently, and buy precious time for firefighting.

From the perspective of maintenance, this mechanism also plays an important role. It can help maintenance personnel to discover potential equipment problems in time, arrange maintenance plans in advance, and reduce the probability of sudden equipment failures. Through long-term recording and analysis of alarm data, maintenance personnel can also summarize the laws of equipment operation and potential failure risk points, so as to formulate more scientific and reasonable maintenance plans, extend the service life of XBC-IS diesel engine fire pumps, and reduce overall maintenance costs.

In actual application scenarios, whether in large industrial plants, high-rise buildings, or crowded public places, the automatic alarm protection mechanism of the XBC-IS diesel engine fire pump has demonstrated strong practical value. For example, in a modern commercial complex, the XBC-IS diesel engine fire pump, as the core equipment of fire safety, is always on standby. Once the fire alarm sounds, the fire pump quickly starts and goes into operation. At this time, if the diesel engine has a low oil pressure fault, the automatic alarm protection mechanism will respond immediately, and the sound and light alarm in the on-site fire control room will instantly emit a sharp sound, and detailed fault prompt information will pop up on the computer screen of the on-duty personnel. After receiving the alarm, the on-duty personnel can quickly organize professional maintenance personnel to inspect and repair the equipment according to the predetermined emergency plan to ensure that the fire pump resumes normal operation in the shortest time and provide continuous and stable water supply support for extinguishing the fire.

The XBC-IS diesel engine fire pump works in conjunction with the intelligent central control system through a precise monitoring system to build an efficient and reliable automatic alarm protection mechanism. This mechanism is not only the key to ensuring the stable operation of the equipment itself, but also an important support for improving the overall fire safety guarantee level. It uses advanced technical means to ensure the smooth implementation of firefighting operations, plays an irreplaceable and important role in preventing the expansion of fire accidents and protecting the safety of life and property, and has become one of the indispensable key technologies in the field of modern fire safety.

English

English 中文简体

中文简体

Home

Home