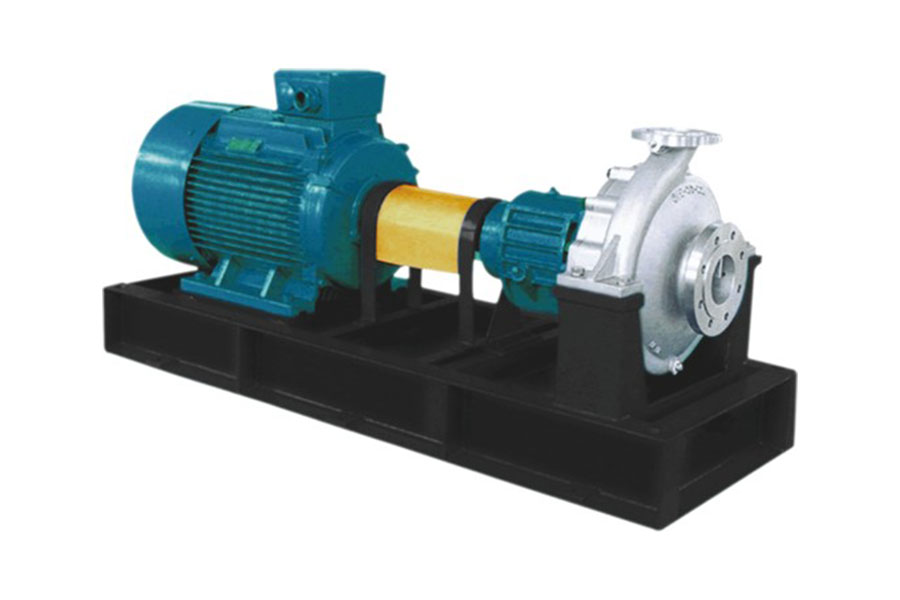

As a special pump designed for conveying corrosive media, the core of IHF fluorine-lined chemical pump lies in the manufacturing process of its key components. Among them, the ""integrated sintering and pressing"" process is an important guarantee for its corrosion resistance.

The so-called ""integrated sintering and pressing"" means that key components such as impellers, pump covers and sleeves are manufactured by using metal inserts to wrap fluoroplastics. This process is not simply wrapping fluoroplastics on metal parts, but through high-temperature sintering and pressing, the fluoroplastics and metal parts are tightly combined to form a whole. This combination method not only ensures a firm connection between fluoroplastics and metal parts, but also effectively avoids corrosion cracks caused by different materials.

Corrosion cracks are the ""hotbed"" for the penetration and erosion of corrosive media. Once there is a corrosion crack, the corrosive medium will penetrate along the crack, gradually erode the pump body, and cause damage to the pump. The overall sintering and pressing process used by the IHF fluorine-lined chemical pump effectively eliminates this hidden danger. The close combination of fluoroplastics and metal parts makes it impossible for corrosive media to find a channel to penetrate, thus ensuring the long-term and stable operation of the pump.

In addition to its excellent corrosion resistance, the IHF fluorine-lined chemical pump also stands out in many industrial fields with its many advantages. Its pump body is uniquely designed, with a metal shell lined with fluoroplastics. This design not only gives the pump body sufficient strength and rigidity to cope with the challenges under various complex working conditions, but also ensures that the part of the pump body that contacts the corrosive medium has excellent corrosion resistance. This double guarantee enables the IHF fluorine-lined chemical pump to maintain stable performance in long-term operation, effectively extending the service life of the equipment.

In terms of efficiency, the IHF fluorine-lined chemical pump also performs well. Its optimized flow channel design and efficient impeller structure enable the pump to fully utilize energy and improve the delivery efficiency during operation. At the same time, the low-energy consumption design also greatly reduces the operating cost, making a positive contribution to the energy conservation, emission reduction and economic benefit improvement of the enterprise.

The structure of the IHF fluorine-lined chemical pump is advanced and reasonable, the various components are closely matched, and the operation is stable, with low vibration and low noise during operation. This not only provides a more comfortable working environment for operators, but also reduces the interference of equipment on the surrounding environment, which meets the requirements of modern industry for environmental protection and sustainable development.

The service life of IHF fluorine-lined chemical pumps is very long. This is due to its high-quality material selection, exquisite manufacturing process and strict quality control. During long-term use, the pump body is not susceptible to corrosion and wear, and the performance of each component can remain stable, thereby reducing the frequency of maintenance and replacement and reducing the company's operation and maintenance costs.

The overall sintering and pressing molding process of IHF fluorine-lined chemical pumps is not achieved overnight, but has matured after long-term research and development and practice. The successful application of this process not only reflects the manufacturer's technical strength and innovative spirit, but also provides users with a more reliable and efficient pump product selection.

English

English 中文简体

中文简体

Home

Home