Green Energy Powers Pakistan's "Three Gorges Project": Bangpu Supports Tarbela Dam Phase V Expansion

Project Background

Hailed as Pakistan's "Three Gorges Project," the Tarbela Hydropower Station, situated on the Indus River, is a "national energy lifeline." Its total installed capacity once accounted for one-third of the nation's power supply, making it a core project supporting Pakistan's energy, agriculture, and livelihoods.

The Tarbela Hydropower Station was constructed in phases. On August 12, 2021, the main works for the Phase V expansion officially commenced. In this Phase V expansion of the "marvel of human engineering," Bangpu pumps will contribute solid technical strength to drive this energy upgrade.

Project Details

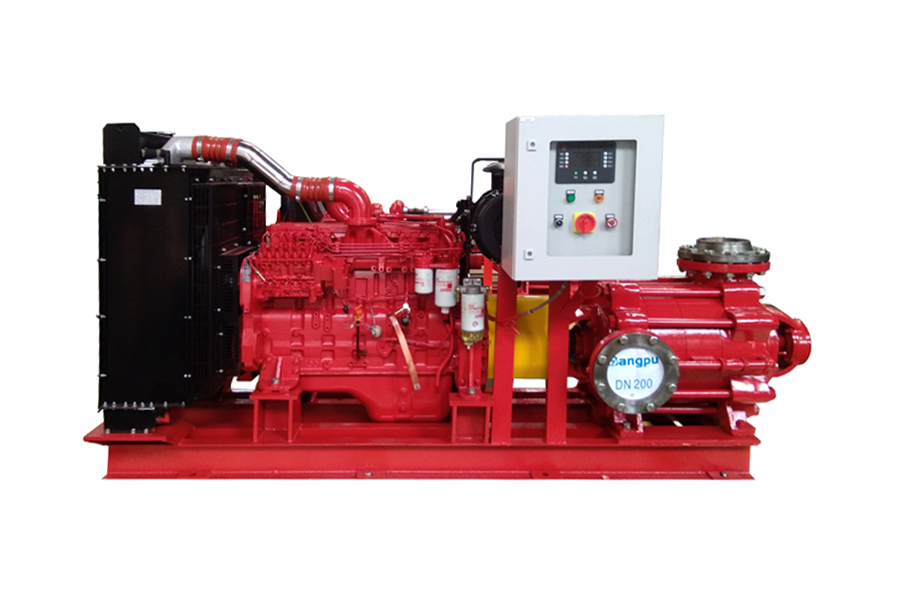

As a well-known pump manufacturer founded in 2008, Bangpu, leveraging its extensive experience in domestic and overseas projects, successfully became a core supplier for the Tarbela Phase V expansion. We customized multiple sets of high-performance pump equipment for this world-class project, using our professional expertise to ensure the project's efficient progress.

The Phase V expansion of Tarbela Hydropower Station is of extraordinary significance. Its three 470MW Francis turbine-generator units are the largest hydro-generating units by capacity in Pakistan. Upon completion, the total generation capacity will increase to 6298MW, accounting for one-quarter of the nation's installed power capacity. This is a milestone for optimizing Pakistan's energy structure and promoting clean energy development. The equipment we provided acts as the "blood circulation system" ensuring the stable operation of this project.

1. Unit Cooling Equipment

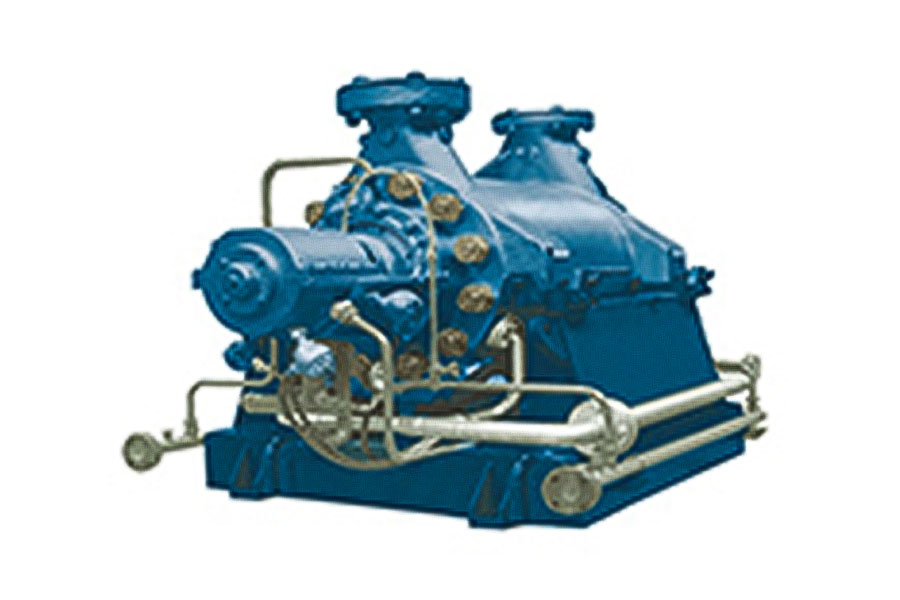

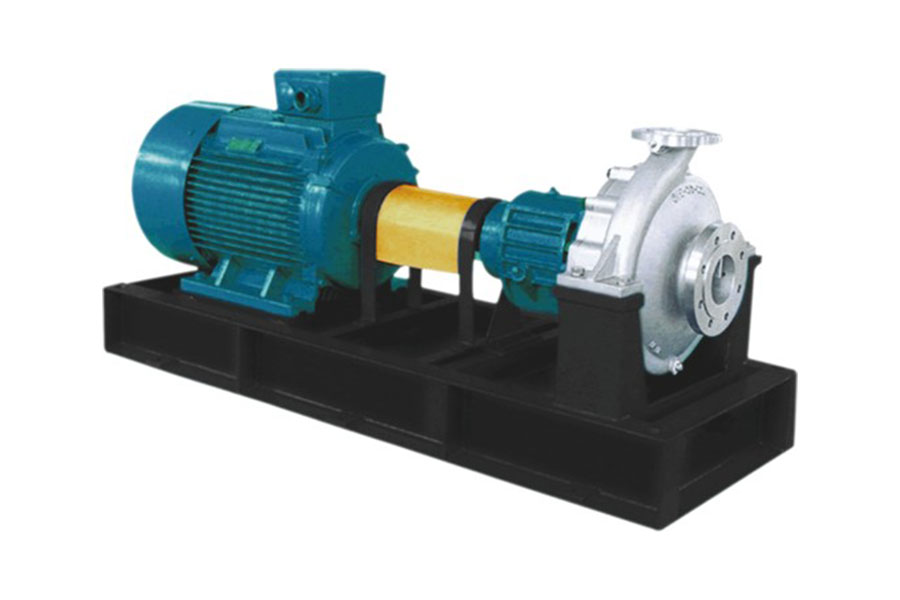

To meet project requirements, we precisely matched various types of pumps: large-flow, medium-low head horizontal split-case centrifugal pump sets became the "core power source" of the technical water supply system. They provide high-pressure, large-flow cooling water for critical areas such as the bearing cooling, generator air coolers, and transformer cooling of the 470MW Francis turbine-generator units. Their stable and reliable water supply capability ensures the units remain "cool" under high-intensity operation, safeguarding generating efficiency and equipment safety.

2. Sediment and Wastewater Treatment

In addressing the challenge of the Tarbela reservoir's annual siltation, two coupled submersible sewage pumps with a capacity of 400m³/h and a head of 65m demonstrated strong "desilting capability." Their high-head design enables efficient operation in the sand discharge galleries, working in conjunction with dredging equipment to rapidly transport sediment, effectively protecting the dam from siltation, and building a solid line of defense to extend the dam's service life.

Additionally, three coupled submersible sewage pumps with a capacity of 1000m³/h serve as "drainage guardians" for the underground powerhouse and galleries. Underground engineering inevitably faces water seepage. These large-flow sewage pumps can quickly discharge water collected in sump pits to the tailrace, ensuring a dry and safe powerhouse and providing a stable environment for construction and subsequent operation. Simultaneously, this indirectly ensures a stable and reliable water source for local agricultural irrigation, allowing the hydropower station's "irrigation" function to be utilized more efficiently.

Delivery Progress

A comprehensive plan goes beyond being "just on paper"; equipment performance and quality are crucial to the project's key operational phases. At the Bangpu testing center, the quality department and inspection personnel meticulously checked performance and appearance indicators item by item according to inspection standards, detailedly recorded and retained test data and inspection reports for each unit, and monitored key operating parameters in real-time to ensure all values met or exceeded design requirements.

Only after thorough and complete testing and inspection, ensuring each unit's performance met standards and quality passed, would the equipment proceed to the next delivery stage. This reflects our commitment to quality and our promise to the customer. In terms of packaging and transportation guarantees, the shipping department approached full protection with meticulous care: multiple waterproof and anti-impact measures for complete units – strict film wrapping, full coverage with waterproof tarpaulin, external wooden crates reinforced with angle steel; individual protection and independent fixing for pump bodies and vulnerable parts, lined with shock-absorbing materials and reinforced at fixing points. Each step followed standardized procedures with inspection records, striving to minimize vibration, impact, and moisture risks during the long transportation journey, ensuring every unit reaches the customer in the same perfect condition as when it left our factory.

English

English 中文简体

中文简体

Home

Home