Against the backdrop of ongoing adjustments to the global energy structure and the accelerating transition toward low-carbon development, the clean and environmentally friendly upgrading of traditional coal-fired power plants has become an important pathway for energy modernization in many countries.

The coal-fired power plant involved in this project was originally constructed in the last century and has long served as a primary source of electricity and heat for the local region. However, due to the inherent characteristics of coal-based power generation, it has also been one of the major contributors to local air pollution.

The “coal-to-gas” upgrade converted the plant’s fuel source from coal to a cleaner alternative—natural gas—while the power plant itself underwent a comprehensive modernization and refurbishment. After the upgrade, pollutant emissions were reduced by approximately 90–99%. At the same time, the use of natural gas further decreased greenhouse gas emissions.

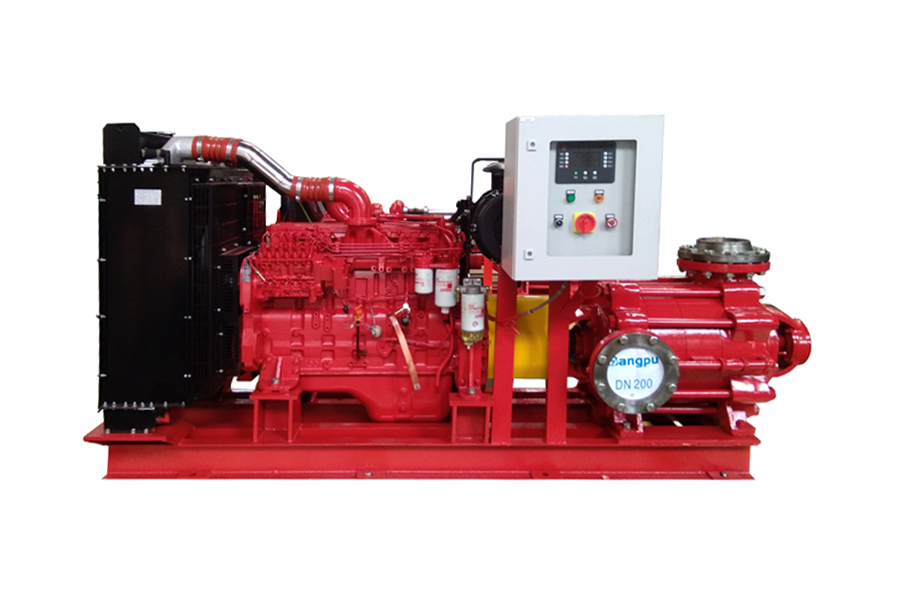

Based on the specific requirements of the project, Bangpu’s technical team carried out equipment selection and updated the design of multiple large-scale conveying systems. These systems provide robust support for the core circulation sections of the newly upgraded units—functioning like a “beating heart” to ensure stable and continuous operation.

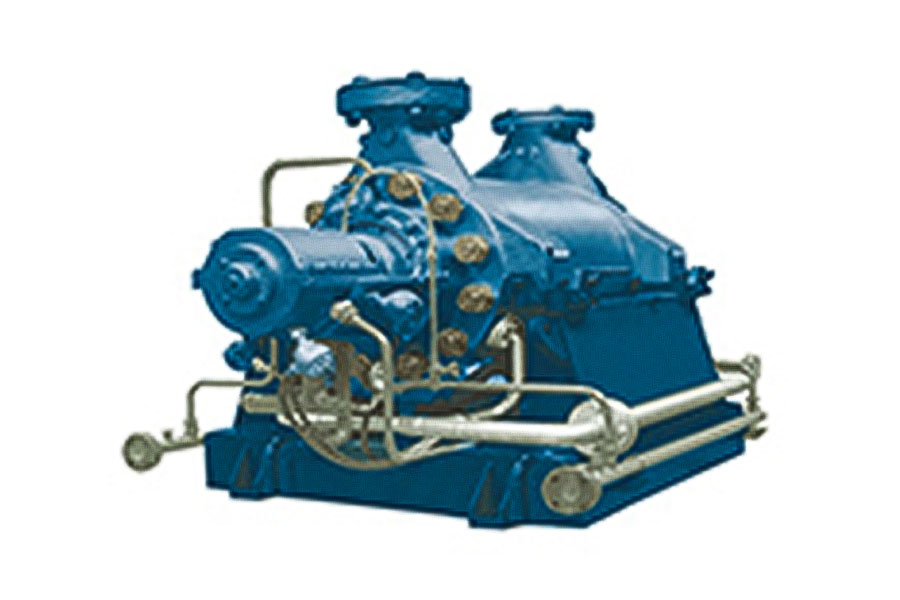

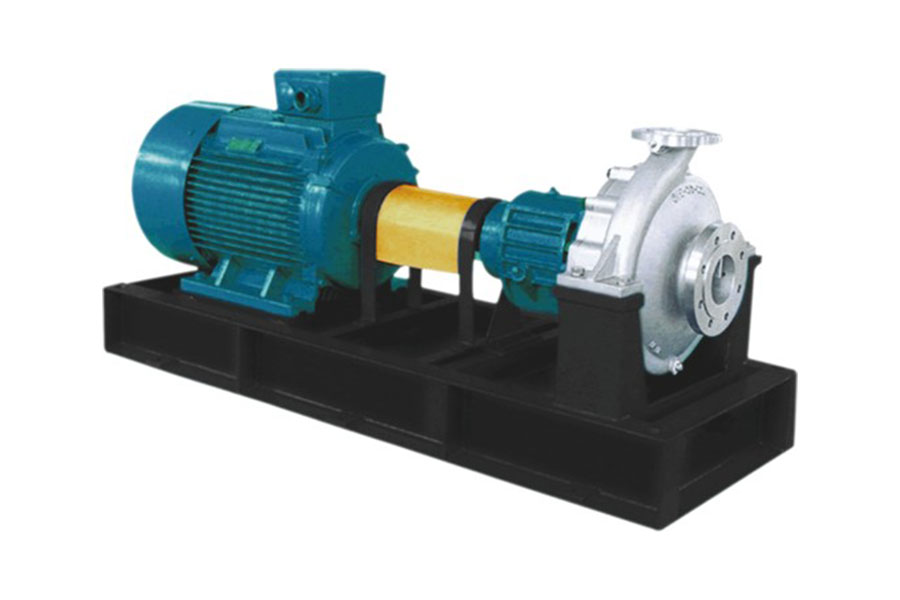

In this project, Bangpu supplied more than thirty units of large industrial pumps to the power station, including double-suction centrifugal pumps and several chemical process pumps. The equipment is primarily used in unit cooling systems, circulating water systems, and related process applications.

Among them, several large double-suction pumps feature single-unit power ratings exceeding 2,000 kW. Their large size and complex operating conditions impose extremely high requirements on hydraulic performance, structural strength, operational stability, and the capability for long-term continuous operation.

During power plant operation, this equipment will undertake critical cooling and circulation tasks, forming an essential foundation for the safe, stable, and efficient operation of the generating units.

In response to the characteristics of coal-to-gas power plants—such as high operating loads, long continuous operating periods, and stringent system stability requirements—Bangpu implemented multiple key enhancements in equipment selection and technical solutions for this project, including:

High-Efficiency Hydraulic Design

CFD-based flow optimization was applied to achieve high hydraulic efficiency and ensure stable operation under large-flow conditions.

Heavy-Duty Structure and High-Strength Material Configuration

Enhanced structural design combined with optimized material selection enables adaptation to high-temperature and high-pressure operating environments, supporting high power output and long operating cycles.

Upgraded Cooling Scheme

An API 682 Plan 53 cooling system was adopted to ensure long service life and stable operation of seals and related components.

This coal-to-gas conversion project is one of the region’s key energy modernization initiatives. Upon completion, it will significantly reduce pollution associated with coal-fired power generation, contributing positively to improved air quality and the optimization of the urban energy structure.

Bangpu’s participation in this project represents not only an equipment delivery, but also a tangible contribution to local energy transition and environmental improvement through the reliable operation of industrial equipment. Since its establishment, Bangpu has continuously expanded cooperation in overseas markets, with its products widely applied in the energy, power generation, water resources, municipal, and industrial sectors.

Through stable and reliable product performance and professional technical services, Bangpu equipment has taken on critical roles in multiple large-scale international projects. Looking ahead, Bangpu will continue to focus on energy upgrading, energy-saving retrofits, and industrial fluid handling, providing overseas customers with more mature technical solutions and highly reliable equipment for long-term, trusted support.

English

English 中文简体

中文简体

Home

Home